Our Services

ServoHyd is an Approved Maintenance organization operation in conformance with the requirement of Transport Iran. IR.145.67

SHP’s integrated manufacturing and production team encompasses design, engineering, and diverse production departments.

ServoHYD has a well-trained team to find the right parts and/or material and if necessary (e.g. hard-to-get, out-of-stock, or obsolete part) a replacement part or material for its scope of work.

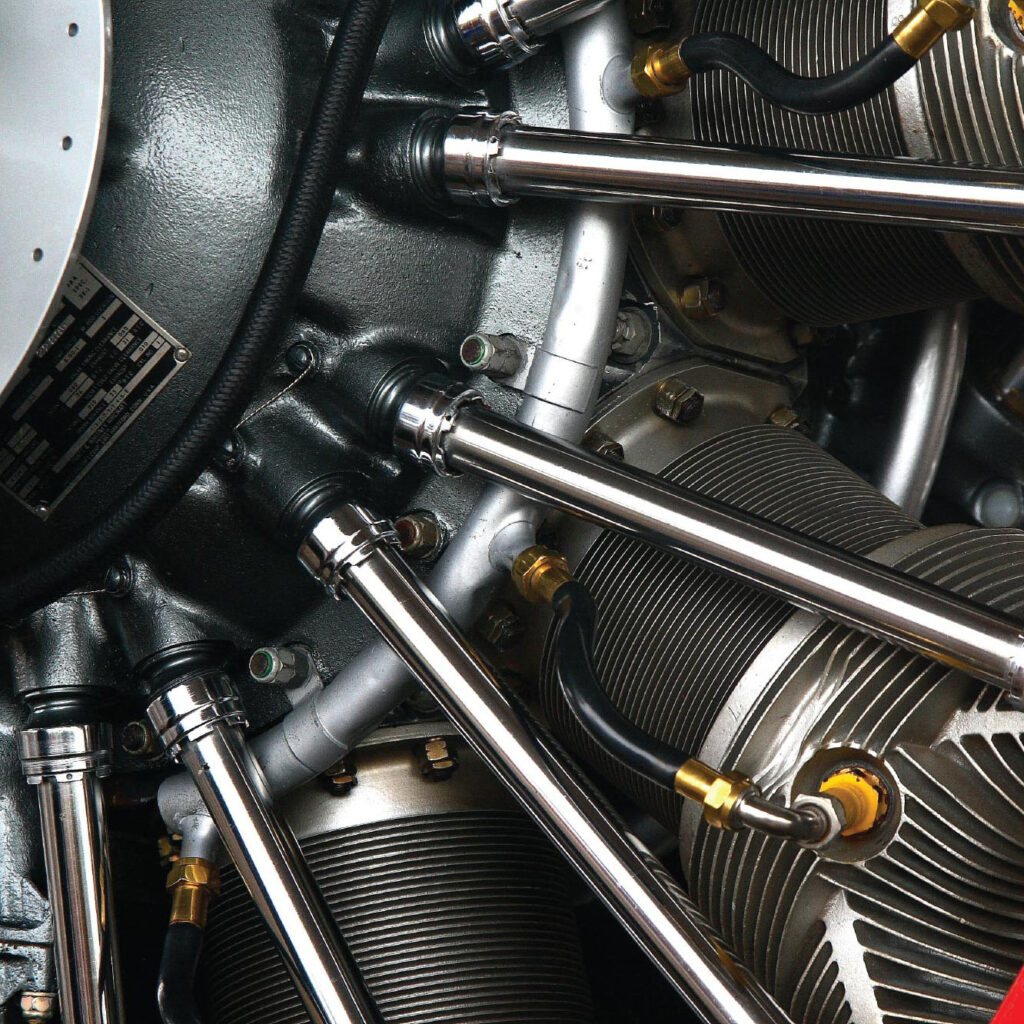

Scope of work

About Servohyd

SERVOHYD was established in 2008 and soon became a knowledge-based company. Today SERVOHYD is a knowledge-based company in 13 different fields according to the recent survey of the Vice Presidency of Science, Technology and Knowledge-based Economy Organization (ISTI) of Iran.

In the beginning, SERVOHYD used reverse engineering methods to produce servo components such as Servo Actuators and Servo Valves according to the customers’ request. Nowadays, SERVOHYD can directly design very complicated hydraulic and pneumatic parts.

SERVOHYD was established in 2008 and soon became a knowledge-based company. Today SERVOHYD is a knowledge-based company in 13 different fields according to the recent survey of the Vice Presidency of Science, Technology and Knowledge-based Economy Organization (ISTI) of Iran.